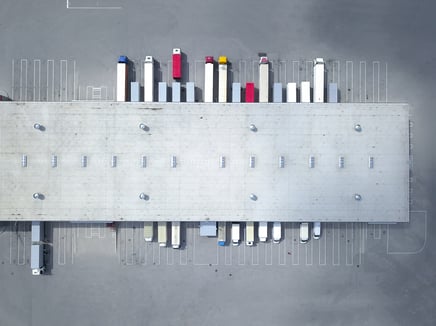

Providing Logistics Services Solutions so you can focus on making your business even better.

At InTek, we utilize our industry expertise, leading-edge technology, and partnerships to offer a wide variety of logistics services that enhance your customer experience, control costs, and allow you to focus on running your business.

![]()

Optimize your logistics costs and resources

![]()

Turn your shipping and logistics into a competitive advantage

![]()

Focus on running your business

![]()

Enhance your customer experience

There are thousands of logistics service providers registered in the U.S. Picking the wrong one can leave businesses…

- Spending more for unreliable service

- Relying on internal solutions that lack broad market knowledge and connections

- Allocating resources away from their core business focus

- Missing out on the best logistics expertise and technology

Hear From Our Customers

"InTek's service commitment is second to none. As a result, InTek is the first non-asset provider to ever receive the carrier of the year award from Guitar Center."

- Matt Sessoms, Transportation Manager, Guitar Center

"When I look at [our previous] 3PL services compared to now, much better value, follow up, service, transparency. We made the right decision."

- Jeff Russett, Director of Transportation, Paperworks Industries

Just a Few of the Hundreds of Companies that Trust Us

Choose InTek for All Your Logistics Services Needs

Consolidate multiple LTL - less than truckload - freight shipments into truckload or intermodal for the long haul to improve transits, reduce claims, get better visibility, shrink your environmental impact and save money. Our MercuryGate TMS technology and extensive network of distribution centers makes it easy.

Shippers often have peaks in their business or short-term projects that surge capacity requirements and stretch their typical routing guide. Rather than letting those scenarios derail your day-to-day, InTek offers an alternative approach. Our Project, Surge and Seasonal Freight Services Management allows you to stay focused on everyday business while we cover spikes in capacity within budget and without the headaches.

The Advantages of a Logistics Service Provider

Logistics service providers offer a variety of tools, technology and services to help business partners transport their freight - or manage the whole transportation operation. For a business, outsourcing freight to a logistics service provider can offer many advantages, including:

- Access to top TMS technology solutions

- Reduction of back-office work

- Increased cost savings and efficiencies

- Ability to leverage the provider’s carrier network

- Increased customer service satisfaction

- Improved risk management

- Ability to easily scale the business

- Immediately gain a competitive advantage in logistics operations

- Access to top logistics expertise

- Improved order-to-cash cycle and ROI

Ready to empower your business with innovative shipping solutions?

Request a Quote

Share information about your business to help us assemble your customized logistics solution. You’ll be introduced to one of our experts to start the conversation on how we can help.

Review Your Proposal

Let’s get your customized logistics solution on the road. After we get to know your shipping needs, we’ll offer options and work with you to determine the right one for your business.

Rely on InTek

Sleep soundly, knowing an experienced operations professional, backed by a team of industry experts, is focused on your long-term success and always available to address any issues. And we don’t stop there. We proactively reach out to troubleshoot and improve your shipping service, so you never have to wonder or worry.

-jpg.jpeg)

Find out why businesses choose to “go managed” with managed transportation solutions

Every shipper is different as to why they choose a managed transportation solution, but the way they get to the decision tends to be the same.

Discover how managed transportation can save you money and how to utilize it to improve efficiency within your company. Learn about the different services offered and dive deeper into the subject of managed transportation with our free “Why Managed Transportation” ebook.

Connect with Us

We’d love to learn more about your business’s unique needs and if we’re the right fit for you.

.png?width=495&name=intek-transloading%20(1).png)