How much does intermodal cost is a question we are often asked. As a leading intermodal marketing company (IMC) we get hundreds of people calling us throughout the year looking for the cost of intermodal and whether it makes sense to transition some of their truckload volume over to intermodal.

While this would seem to be an easy question to answer, there are a number of variables that cause the price to change.

With the critical nature of supply chain decisions because of their impact to a company’s success, we thought we would provide as much transparency to the pricing of intermodal lanes to help shippers in their quest to improve their logistics team’s performance to optimize their supply chain strategy.

The key concept to hit before breaking down intermodal cost is to understand that the reason intermodal is often the cheaper 53’ capacity mode over truckload is because intermodal takes advantage of the best characteristics of intermodal and the best attributes of truckload.

Those characteristics are:

-

Intermodal is extraordinarily efficient at moving the long haul portion of the origin / destination pairing.

-

To put an exclamation point to this topic, we pulled the following quote from the CSX railroad where it states “intermodal is 4 times more efficient than moving freight on the highway with trains capable of moving one ton of freight over 470 miles on a single gallon of fuel”.

-

Truckload is incredibly flexible and efficient in moving freight from any point to any point over-the-road.

The combination of both these freight mode attributes create tremendous value for shippers hauling freight more than 700 miles and is the basis for intermodal costing and what makes for a great intermodal freight lane.

Pricing Intermodal Transportation Freight Lanes

While there are a number of differences between intermodal and truckload, which we outlined in the article entitled “11 Differences Between Intermodal and Truckload Every Shipper Should Know”, the pricing is done very similar with the cost being the linehaul rate, plus fuel.

The intermodal service provider does its internal cost work to determine the market pricing by breaking linehaul and fuel down into further components:

-

Linehaul

-

Dray from the origin warehouse / manufacturing site to the origin intermodal ramp.

-

Rail line haul cost, with interline fees if the intermodal container needs to transition from one railroad to another.

-

Dray from the destination intermodal ramp to the destination to the ultimate customer or customers if it is a multi-stop load.

-

Fuel

-

Fuel cost is driven by a matrix the IMC uses that is typically built off the US Energy Information Administration (EIA) rates that are posted every Tuesday.

With the components of intermodal costs known, it is much easier to determine the costs and what could be an optimal lane for shippers to convert from truckload to intermodal.

The Attributes of a Good Intermodal Lane

-

The intermodal linehaul is 700 miles or greater.

-

The longer the linehaul the greater the percentage of the total trip will be riding on the railroad efficiency.

-

It is optimal when the origin and destination dray segments of the shipment are not greater than 100 miles.

-

The additional point here is if you have a higher volume lane where the dray driver can drop and hook versus drop and leave, then the turn will produce efficiencies that allow the dray miles to extend and still make for a good intermodal lane.

-

-

The shorter the dray from the intermodal ramps the better.

-

As the length of the linehaul increases, the greater the dray miles can be for an intermodal lane to work, so don’t rule out lanes where the dray will be greater than 100 miles.

With the basics of the cost of intermodal shipping behind us, let’s dig into a few more points about the cost of intermodal.

There are a few issues that keep truckload shippers on the sidelines, which we addressed in “Do You Really Know Intermodal? A Look at the Common Misconceptions”. While many of the concerns are misconceptions, one area that is not a misconception is if an intermodal shipment is not handled properly accessorial charges can become a reality.

To be clear and transparent here, accesorials are unexpected charges no one likes, including the IMC moving the load for the shipper. The amount of work that comes with these unexpected issues cause delays in the shipment, create frustrations and often times damage relationships. To sum it up, the load is a complete loss for all parties.

The good news is many of the accessorials can be avoided with understanding the rules and regulations that could possibly become a problem for a shipment, which we will address now.

The Watch Outs that Drive Intermodal Shipments into the Accessorial Schedule

The typical accessorial charges associated with intermodal shipments are:

-

Detention

-

Charge is associated with a container being held more than 2 hours at either the origin or destination dock.

-

Demurrage (Storage Charge)

-

It is important to note that congestion or a location being closed is not a free pass. The clock will continue to run.

-

-

Charge is assessed by the intermodal ramp when the cargo is left beyond the allotted free time. The charge escalates as the number of days increases.

-

Per Diem

-

A fixed rate per day charged against another carrier for use of its container, trailer or chassis.

-

Re-Work

-

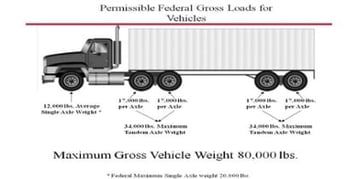

Over 95% of the weight issues are related to a load shifting in transit and to correct the load is sent to a facility to be reworked back to a legal weight limit. For more information on this topic, we’d recommend our most read blog: Intermodal Weight - The Most Common Issue for Shippers.

-

-

Intermodal weight is the number one issue associated with intermodal and when there is a weight issue re-work always becomes a part of the equation to fix the problem. (The topic of weight alone is a huge frustration for shippers, as weight has more issues around it than just being 80,000 pounds in total. There is also weight requirements with the amount of weight on the axle and steer, along with bridge weight requirements.)

Intermodal weight is the number one issue associated with intermodal and when there is a weight issue re-work always becomes a part of the equation to fix the problem. (The topic of weight alone is a huge frustration for shippers, as weight has more issues around it than just being 80,000 pounds in total. There is also weight requirements with the amount of weight on the axle and steer, along with bridge weight requirements.)

While accessorials are an unloved topic, as we mentioned earlier, they can be avoided with planning and management.

The top two ways to avoid the most common and costly demurrage charges:

-

Know the storage and demurrage rules.

-

Once the rules are known be diligent in managing to the free time and be aggressive with moving the freight quickly to its destination. If there are multiple containers to move make sure you coordinate and communicate well with your dray provider to move the oldest container first.

-

Block and brace the intermodal shipment.

-

Weight shifts will not happen when a shipment is properly blocked and braced, so do not cut corners on the blocking and brace activity. If you are not sure how to best load your shipment, your intermodal provider will engage the class I railroad associated with the load to assist in every way possible, up to and including a site visit.

3 Types of Intermodal Pricing: Contract, Spot Rate and Project

The final topic to cover are the various pricing options within the intermodal market.

Contract Intermodal Pricing and Best Time of Year for RFP

We’ll start with contract versus spot rate pricing. Both types of pricing models have their place in the freight market, but for shippers having the necessary volume it is to their advantage to negotiate annual intermodal freight contract pricing with guaranteed capacity. Their are volume requirements that have to be cleared to obtain annual contract pricing.

The best time to go out for contract pricing is at the beginning of the 1st quarter. Now, I can hear financial departments throwing up their arms because they have their annual budgets due prior to year-end, but keep in mind that while it may be the best time for budgets it is suboptimal for intermodal contract rate negotiations.

The reason it is the worst time of the year to go out for a freight request for proposal (RFP) is the 4th quarter is typically the highest freight volume quarter of every year. Pricing departments tend to price based on what they know at the time, meaning they see volumes and dollars dancing in their heads in the 4th quarter holiday season. So, with that in mind, a few weeks into the first quarter is better, with volumes on the decline after the holiday season.

Spot Intermodal Pricing and When to Use

Spot rates are an option for shippers not having the volume to obtain guaranteed capacity contract pricing or when shippers require additional capacity to cover their freight volumes in a particular lane. Spot rates can be volatile because the spot market is a function of supply and demand, meaning the higher the demand the higher the price. There is some predictable seasonality in the spot rates, so we would recommend working with an IMC that has a thorough understanding of the intermodal market to help guide you through the spot rate waters.

A great resource to track the favorability / unfavorability of the spot intermodal market is to become an instant subscriber to the InTek blog, where the intermodal spot market index is published weekly. Also, for more on spot and contract pricing read Understanding Intermodal & Truckload Spot Market Pricing.

Intermodal Project Pricing

The last option for intermodal pricing is project based pricing. Project pricing means pretty much what you would think it would based on the name. For shippers having a special project that will produce volumes outside the “norm”, then this is your option. It allows shippers to obtain advantageous short term pricing over the period of the project. Depending at the time of the year, this option produces tremendous value and capacity for shippers. Keep in mind that if you are a season shipper, the volumes your company produces over a short period of time could be enough to push you into a project based pricing contract.

To sum it up, shippers have a great deal of options to explore in their quest to find value in their supply chains utilizing 53’ domestic intermodal. We would love the opportunity to be a part of your journey in exploring intermodal within your logistics team’s strategy discussion, but understand there are many options out there as described in the top intermodal companies blog recently published.

For a deeper dive into intermodal, we recommend reading our in-depth article entitled The Completed Guide to Intermodal Transportation, which is comprised of the following chapters:

- INTERMODAL VS. TRUCKLOAD SHIPPING: A SIDE-BY-SIDE COMPARISON

- IS INTERMODAL TRANSPORTATION THE RIGHT FIT FOR YOUR COMPANY?

- COMMON ISSUES AND MISCONCEPTIONS AROUND INTERMODAL TRANSPORTATION

- THE BENEFITS OF INTERMODAL TRANSPORTATION

- THE COST OF INTERMODAL TRANSPORTATION

- GETTING STARTED WITH INTERMODAL TRANSPORTATION

If you're ready to take the next step, at InTek Freight & Logistics, we can help. Just tell us what you need and we'll discuss how our expertise can help with the unique shipping challenges your business faces. Rather do a bit more research first? View our Freight Guides for comprehensive articles and eBooks on all things freight and logistics.

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (54)

- Freight Broker (60)

- Freight Forwarder (2)

- Intermodal Transportation (185)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (421)

- Logistics Service Provider (77)

- LTL (39)

- Managed TMS (49)

- News (39)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (122)

- Warehousing & Distribution (50)