For three of the last four years, shippers have been struggling with 53’ freight capacity challenges brought on by weather disruptions, economic swings, labor shortages, equipment shortages and the COVID19 global pandemic.

For three of the last four years, shippers have been struggling with 53’ freight capacity challenges brought on by weather disruptions, economic swings, labor shortages, equipment shortages and the COVID19 global pandemic.

The freight capacity problems came from both truckload and 53' domestic intermodal.

Based on this recent history, the expectation in the industry is for freight capacity constrained markets to be more the norm than a one-off situation.

The by-product of freight capacity challenged markets is lower on-time freight delivery service levels and higher freight prices.

While the majority of a logistics professional's efforts is in finding additional freight providers in the open market to supplement one’s own current inbound and outbound freight routing guides, shippers should not ignore the areas they can control within their operations.

The reason for addressing the interndal controllable variables is it comes at no additional cost and lessens the challenges of finding the next truck to meet their customers’ requirements.

Over the next several paragraphs we will look at those areas where shippers can concentrate their logistics team to help alleviate the cost and service issues they are faced with in a constrained freight market.

Top 6 Internal Measures Shippers Can Take to Lessen Freight Capacity Challenges

- Institute Drop Pools vs Live Loads

- Use Window Appointments vs Specific Appointments

- Listen to Your Current Pool of Trusted Freight Providers

- Be Flexible on the Pick-up Day

- Use TOFC Intermodal

- Not All Outbound Freight Lanes Are Closed in a Given Market

Institute Drop Pools vs Live Loads

Providing drop trailer or container options for freight carriers allows them to better manage their most valuable assets, their drivers, to the fullest possible extent. It’s amazing to see how many hours in a driver’s day is wasted sitting at either the origin or destination dock to be loaded or unloaded versus moving freight to the next location.

Providing drop trailer or container options for freight carriers allows them to better manage their most valuable assets, their drivers, to the fullest possible extent. It’s amazing to see how many hours in a driver’s day is wasted sitting at either the origin or destination dock to be loaded or unloaded versus moving freight to the next location.

The more shippers control their docks and how freight moves through them in a manner that respects the time of the driver, the more the motor carriers will be willing to help in capacity and price.

Taking this action also pays forward the hours to others in the markets where your company’s freight is being delivered. The reason for this is because it gives the driver that just unloaded at your facility an opportunity to move additional loads over the course of the day.

Use Window Appts vs Specific Appts

If drop pools are not an option for your facility because of space, then the next best option for your facility is to give freight providers appointment windows to be loaded or unloaded versus specific dock times.

If drop pools are not an option for your facility because of space, then the next best option for your facility is to give freight providers appointment windows to be loaded or unloaded versus specific dock times.

Again, this suggestion has to do with giving the most flexibility to the drivers moving your company’s freight to maximize their time moving loads versus sitting at customer docks.

Listen to Your Current Pool of Trusted Freight Providers

The quote attributed to the Greek philosopher Epictetus, “we have two ears and one mouth, so that we can listen twice as much as we speak,” stands to this day.

The quote attributed to the Greek philosopher Epictetus, “we have two ears and one mouth, so that we can listen twice as much as we speak,” stands to this day.

Your trusted motor carriers and freight brokers are in the market everyday for your business and others. This gives them a tremendous amount of first-hand information that helps them best serve your business with the most up to date information on where capacity can be found at the best possible price.

Not only is the information invaluable, but it is free.

The end result of tapping this source of information is it is real-time and actionable.

Be Flexible on the Pick-Up Day

The phrase “patience is a virtue” stands strong in a tight truckload and intermodal freight market.

The phrase “patience is a virtue” stands strong in a tight truckload and intermodal freight market.

The ability to exercise flexibility is the difference between finding service on your freight lane and reducing your freight costs by 20% or more.

For some perspective on this topic, frequent readers of the InTek blog often hear us talk about freight being part of a fluid network constantly seeking balance.

Freight balance occurs on the macro level of the total North American freight and on the micro level of individual origin - destination freight lanes.

On the macro level, balance is about are there enough trucks in the market to meet the demand of shippers and on the micro the view is based on whether a location is a backhaul, headhaul or one-way market based on its balance. A backhaul market indicates the region / city has more inbound freight traffic than outbound, while a headhaul or one-way market has more outbound freight than inbound.

The reason all this matters is the micro level freight market is never balanced and is where shippers live, motor carriers operate and freight brokers thrive and flexibility pays off in having more success.

Use TOFC Intermodal

Quite often when shippers struggle with their 53’ OTR truckload capacity, they look to freight brokers and to 53’ COFC (container-on-flatcar) intermodal.

Quite often when shippers struggle with their 53’ OTR truckload capacity, they look to freight brokers and to 53’ COFC (container-on-flatcar) intermodal.

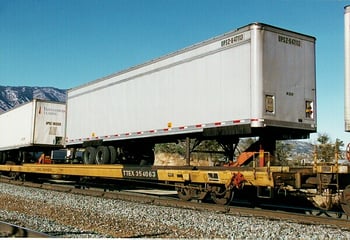

The often overlooked 53’ freight capacity option is TOFC (trailer-on-flatcar) intermodal service.

In a constrained freight capacity market TOFC is a perfect option because of the following characteristics:

- Faster Transit than COFC Intermodal Service

- Spot Market Pricing is Between Truckload & COFC Intermodal

- Does Not Require Gate Reservations

- Does Not Require an Intermodal Chassis

Not All Outbound Freight Lanes Are Closed in a Given Market

The topic of lanes being closed to service is one that 53’ COFC domestic intermodal shippers sometimes run into because of weather or extreme freight capacity situations.

The topic of lanes being closed to service is one that 53’ COFC domestic intermodal shippers sometimes run into because of weather or extreme freight capacity situations.

The point here is that intermodal is managed by ramp pairings, meaning origin and destination railroad intermodal ramps are managed to the goal of equal amount of inbound intermodal containers to an equal amount of outbound intermodal containers.

So, if a shipper hears a ramp is closed, it is worth exploring that comment further to find the origin-destination (O-D) pairings that are not being serviced because it is often not the case where all O-D pairings are closed unless the railroad has announced they are not accepting any intermodal ingates to the intermodal ramp.

Conclusion on Top 6 Internal Steps Shippers Can Take to Improve Truckload Capacity in a Freight Constrained Market

While the six previously mentioned steps discussed in this article will not solve all freight capacity issues, they do put businesses in a better position to succeed and they are actions that can be controlled by the company themselves.

For more on freight capacity solution challenges, please visit the InTek website and Learning Center for more information about us and potential solutions we've put in place to help shippers.

Below is a small sample of our more in-depth papers on key topics shippers have found useful in managing through their freight and logistics challenges that you too may find helpful:

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (53)

- Freight Broker (58)

- Freight Forwarder (2)

- Intermodal Transportation (182)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (415)

- Logistics Service Provider (76)

- LTL (39)

- Managed TMS (49)

- News (38)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (121)

- Warehousing & Distribution (49)