As we have shared previously, less-than-truckload (LTL) can be one of the most difficult freight moves to get “right”. Between NMFC class ratings, confusing tariff schedules, various service coverage maps and claims, there is plenty in play that can take a great deal of energy away from other priorities in a shipper’s logistics and supply chain strategy.

As we have shared previously, less-than-truckload (LTL) can be one of the most difficult freight moves to get “right”. Between NMFC class ratings, confusing tariff schedules, various service coverage maps and claims, there is plenty in play that can take a great deal of energy away from other priorities in a shipper’s logistics and supply chain strategy.

With all the moving parts LTL brings, the priorities of cost and service often takes a back seat to just getting the product from your dock to the ultimate customer at a better cost than last year.

At some point in a company’s life cycle, pushing LTL pricing improvement on volume increases will end and the finance team will want more, and this where the topic of freight consolidation begins.

Definition of LTL Freight Consolidation

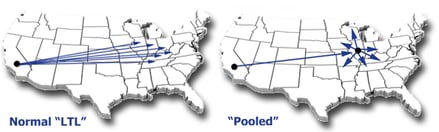

For those new to LTL freight consolidation, it is a logistics freight strategy where a shipper combines multiple LTL shipments within a particular geographic region into a truckload or intermodal that is then line hauled to a destination point where the shipments are broken down and shipped LTL to their final destination.

With an LTL freight consolidation strategy, a shipper is essentially converting its LTL volume to truckload. So, instead of shipping direct from the origin to the destination with multiple LTL carriers, the shipper is consolidating all the shipments onto a truckload to then make final delivery with local cartage for the individual shipments.

Operationally speaking, orders are loaded onto a 53’ dry van or intermodal container until full, then shipped to a regional terminal or distribution point for delivery to various consignees within that geographical region. The process at the destination terminal is the truckload is offloaded, segregated and sorted by consignee then sent for delivery on local trucks for consignee deliveries.

Example

The illustration to the right outlines a pool distribution strategy where a shipper has a DC / manufacturing site in Southern California, with a Midwest customer base. In this illustration, the shipper executes a load plan that includes several LTL carriers pick-ups in SoCal for a couple dozen shipments. Each LTL leaves the DC, as a single shipment, and is then crossed docked for the final deliveries.

Benefits of an LTL Consolidation Program

While LTL consolidation programs are mainly thought of as an opportunity to reduce LTL freight costs, there is a host of other benefits, as you can see below.

Top 10 Benefits of LTL Freight Consolidation

-

Reduce LTL Freight Cost

-

Pricing Simplicity

-

Improved Transits

-

Fewer Touches thus Reducing Claims

-

More Transparency on Shipment Status

-

Less Congestion on Shipping and Receiving Docks

-

Fewer Carrier Relationships Required

-

Reduce Accessorial Charges

-

Sustainability

-

Higher Service Level

To understand each of the benefits further, let’s go through each in more detail.

Reduce LTL Freight Cost

The typical savings a shipper can expect ranges between 10% to as high as 50%. The wide variance in savings expectations comes from the characteristics of the shipper’s LTL freight.

The savings is obtained in the consolidation process, where the truckload linehaul costs are significantly cheaper than the linehaul costs of hub and spoke LTL model. Also, keep in mind, domestic 53’ intermodal is another way to drive down the linehaul costs.

Savings also come from the LTL shipments not having to move under the NMFC LTL rating classes. Higher class LTL freight picks up a tremendous advantage for LTL consolidation over standard LTL shipping methods.

An LTL consolidation program is also an alternative to save on LTL spend through a multi-stop truckload strategy. The reason for this is multi-stop truckload has, for many shippers, gone by the wayside with HOS rule changes and truckload providers escalating each subsequent stop charge to account for the regulation.

In addition to the cost factor of multi-stop truckloads, the problem of meeting the retailers’ RAD delivery requirements when the first delivery is missed is eliminated in an LTL freight consolidation program because the final deliveries are not daisy chained together, thus eliminating the domino effect of the subsequent deliveries all being late. The time and frustrations created with this happening, along with the penalties associated with the late deliveries the retailers apply will convert all the savings to major cost overruns.

Pricing Simplicity

Instead of using complex algorithms to determine LTL costs per each shipment, shippers will find the pricing to be extremely easy with local cartage and truckload costs allocated by either pallet or density. When operating under a managed transportation service solution, as many of these programs operate, the cost is simplified further by being a straight pass through of the carrier costs used in the freight consolidation that the logistics service provider (LSP) will audit for you.

Again, a freight consolidation program eliminates the NMFC LTL rating schedules.

Improved Transits

In addition to the operational time savings of tendering freight for each LTL shipment to the proper LTL provider that will make the delivery, shippers experience quicker delivery times because a shipment does not go through the LTL hub and spoke network.

As an example, a cross-country shipment can take 5 days through a standard LTL program, but only 3 days using freight consolidation.

It cannot be underestimated how much load consolidation simplifies the understanding of multiple LTL carrier transits maps.

Fewer Touches thus Reducing Claims and OS&D

With LTL freight consolidation, product is touched far fewer times as it reaches its destination. Typically with a LTL freight consolidation, a shipment is touched 2 to 3 times where an LTL shipment involves multiple trucks and multiple cross docks into its journey.

Each touch increases the opportunity for damage.

Also, each cross dock opens up the opportunity for multi pallet freight shipments to get separated, which creates headaches in answering and tracking why a shipment was not shipped complete to a customer and / or having to work through the over short and damage process (OS&D).

More Transparency on Shipment Status

Tracking and tracing for a high volume LTL shipper has its challenges as their shipments move from origin to destination. Each shipment has its unique tracking number from point A to point B.

Under a consolidation program, multiple shipments ride the majority of the time on a single tracking number to only be broken out at final delivery or when the consolidation is on the front end in an inbound freight management service solution the opposite occurs with shipments moving into the consolidation point, to then be tracked under a single bill of lading (BOL) to its final destination.

The transportation management system (TMS) used in a freight consolidation program provides real-time tracking notifications for key events through to final delivery.

Less Congestion on Shipping and Receiving Docks

Dock congestion relief is one benefit often overlooked within a freight consolidation solution.

Since there are not multiple LTL carriers coming in and out of a distribution facility over a course of a day, but instead a single truck, the shipping and receiving docks are far less congested. This provides smoother, more timely and accurate dock activities.

Fewer Carrier Relationships Required

Most, but not all, shippers will use a logistics service provider (LSP) to help them with their freight consolidation programs because of TMS technology and access to pool point docks for the consolidation and deconsolidation of freight through the shipping process.

The LSP will run the operation through its managed transportation service solution, which means the logistics service provider will manage all the carrier relationships required in the consolidation.

Depending on how the consol program is set up, will depend on whether the LSP will also provide the freight audit and pay functions making for a much simpler and condensed solution versus the typical LTL model.

Reduce Accessorial Charges

LTL shipments are notorious for their ability to drive accessorial charges. By converting the shipments from multiple LTL’s to a single truckload the opportunity for the possibility of having an accessorial charge assessed is dramatically reduced.

Sustainability

The carbon footprint improves under LTL consolidations because there are fewer trucks in the solution. When intermodal can be introduced, further improvement can be had in the linehaul.

Not only is the carbon footprint reduced, but road congestion is as well.

Higher Service Level

The end result in all the benefits just listed is a higher service level of service for all stakeholders, at a reduced price.

The introduction of an LSP simplifies the execution for the shipper. They live freight consolidation daily, enabling their team to develop expertise on your products and routes and to develop relationships with the DC pool providers that will be handling your last-mile pick-up and / or delivery.

Freight Characteristics Associated with LTL Consolidation Programs

Not every shipper has the ability to operate a LTL consolidation program, so let’s take a quick look at the two key characteristics required to see if a consol program is an option for your company.

Volume & Frequency

The number one characteristic of a successful LTL pool consolidation program is a high frequency of LTL shipments. Notice we did not say high volume of shipments. Yes, volume improves the chances of running a consolidation on a given day, but not 100% required for a consolidation program.

With the above in mind, shippers should consider a hybrid of LTL consolidation and standard LTL shipments. We will walk through the execution later in the article, but just know there are tremendous savings to be had by reviewing consolidations on a given day based on density and delivery dates. When consolidations cannot be assembled for savings, then roll the LTL shipments through the typical LTL providers.

Geographic Density

The second characteristic is a shipper’s LTL volumes have a geographical density that the freight can be routed through regionally to then make the “last-mile delivery”.

Again, teaming with a freight management logistics provider can execute easily through their network of cross-dock providers.

How to Execute a LTL Freight Consolidation Program

The key to executing a successful LTL freight consolidation is: robust technology, communication, strong carrier and pool point relationships and data.

While all the above points are key, without good data communication between the order management system (OMS) of the shipper and a TMS the program will struggle to meet the designed goals.

Data Required

The following is the list of data elements required for an LTL freight consolidation analysis:

-

Origin city, state, and zip code

-

Destination city, state, and zip code

-

Delivery Date

-

Weights

-

Dimensions

-

Freight class

There is quite a bit of information to process in a short period of time to assemble a consolidation and this is where technology comes into play. Technology brings together order information, along with the freight characteristics of each LTL shipment and runs it through a number of logistics algorithms to determine the least cost approach to move the LTL shipments under one BOL, yet still make the delivery requirements.

The next step in leveraging the technology is to optimize the possibilities found in consolidations, pooling, multi-stop runs and optimal tariff selection. It is critical to ensure the analysis is generating real-life solutions. What we mean by real-life solutions is be aware that not optimization tools are created equal. To transform data into real-life LTL freight consolidation solutions it needs to account for LTL and truckload shipping practices, dock performance and characteristics, hours of service, etc. If the analysis does not incorporate these topics., along with industry knowledge, the analysis will be nothing more than a spreadsheet exercise that will never meet expectations.

The following is an example to put an exclamation point to the theoretical analysis that missed real-life situations. In this example, a shipper received what we often call a "spreadsheet analysis" on their shipments with multiple 3-stop and greater shipments into grocery warehouse locations. Experience would say that one of three things are incorrect with such an analysis and should have thrown up the red flags:

-

Grocery warehouses are well known to have dock challenges that slow deliveries and pick-ups.

-

Many trucking companies do not want their assets at grocery locations.

-

If the carrier will allow its assets to be directed into a grocery location, they will not guarantee multiple stops of 3 or more or they escalate their stop-off fees to make the costs uncompetitive against the baseline.

The shipper in this example instituted the TMS of the analyzing company and never obtained the promised savings and improved KPI's.

(We apologize for the detour on this article, but have seen these situations too many times not to point it out.)

Getting back to the analysis itself, the optimization process will be run multiple times to find the consolidation, pooling, multi-stop and rate optimization. Each run will include various assumption changes, with some examples of changes provided below:

-

Incorporating other LTL provider tariffs that may be a better fit for the shipper.

-

New rate structures for current LTL providers brought into the analysis.

-

Incorporate various truckload carriers for the consols and incorporate domestic intermodal when possible.

-

Change pool points to find optimal pool locations.

The TMS will go through multiple iterations until it finds the optimal solution. They create the load plans, print out the BOL, tender the freight to the carriers and put the plan of shipments in motion for the LSP consolidation team to execute from pick-up to final delivery, all the while providing feedback to the shipper on the progress.

Those shipments that cannot be put within an LTL consol will be sent out under the typical LTL carrier process.

Not all organization have the TMS technology, which is why it makes sense to consider an LSP to make the freight consolidation solution a reality. This is not to say that a shipper cannot do freight consolidations on their own, as many shippers do have the technology but as outlined previously there is more to the equation.

The LSP has the ability to access significantly more carriers and pool point options shippers typically do not have within their four wall relationships to allow the freight to move expeditiously, as planned. Without the pool point connections, many consolidations will not be viable because the relationships could not be developed in the time required to make delivery.

Temp Controlled LTL Freight Consolidation

While pooling is a great cost reduction strategy for dry cargo, it is a tremendous solution for temp controlled freight, where there are a limited number of LTL carriers specializing in reefer freight.

This limitation of service offerings drives up costs, limits capacity and requires shippers to time their freight out with the national reefer sailing schedules, which does not always align with their retail customer base.

An industry that practices temperature controlled freight consolidation is the confectionary shippers.

These shippers have found that a temp consol LTL program improves transit times and allows for better adherence to RAD dates for their temp controlled LTL over national temp LTL motor carriers’ sailing dates.

Benefit of Employing Logistics Service Providers (LSP) Consolidation Services

We have touched on the concept of using an LSP in a freight consolidation solution for the following reasons:

-

Identification of freight consolidation and pooling opportunities.

-

Robust carrier and DC network.

-

Robust TMS with optimization, management and reporting technology.

-

Ability to scale with like shippers.

-

Ability for on-site or off-site consolidation programs.

-

Minimize administrative effort needed to build out the solution over multiple LTL providers.

Thes benefits listed help when shippers:

-

Do not have the volumes necessary to create a successful LTL consol program.

-

Data required and the flow of the data is a challenge internally.

-

Internal systems are not robust enough to crunch through the data to efficiently sift through and prioritize the LTL opportunities.

-

Lack of internal resources and network to work through and manage the daily details.

-

Lack the internal knowledge and carrier and DC resources to bring the freight consolidation program up and keep it operationally successful.

Closing Comments on LTL Freight Consolidation Solutions

LTL freight consolidation and pool distribution represents an opportunity for shippers to find a superior and cost-effective alternative to the costs of the garden variety type LTL service most shippers are familiar using in their transportation strategy.

Remember LTL is not an all or nothing thing. On any given day LTL consolidations cannot be created, the orders can be pushed back through the “normal” LTL shipping process.

We did cover that the introduction of an LSP into the LTL consol process can be helpful, keep in mind that there are multiple third-party logistics companies and freight consulting providers that do this for a living. Not all solutions are created equal, so find the one that is the best fit for you.

If you found this article useful and you want to take an even deeper dive into freight costing and pricing to put you in the buyers seat we recommend the comprehensive article entitled Freight Costs: An Insider’s Look on Freight Pricing Buyers Should Know.

If you're ready to take the next step, at InTek Freight & Logistics, we can help. Just tell us what you need and we'll discuss how our expertise can help with the unique shipping challenges your business faces. Rather do a bit more research first? View our Freight Guides for comprehensive articles and eBooks on all things freight and logistics.

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (52)

- Freight Broker (58)

- Freight Forwarder (2)

- Intermodal Transportation (180)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (413)

- Logistics Service Provider (76)

- LTL (39)

- Managed TMS (49)

- News (38)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (120)

- Warehousing & Distribution (49)