Companies often find themselves staring down a warehouse / DC move because:

- There is a need to gain operational efficiencies the current facility cannot deliver upon

- Add additional space or build out a network of DC's

- There are more favorable lease opportunities at the time the lease expires

- Customer mix and / or requirements drive the change

- Government incentives become available

Whatever the reason, the best way to describe a DC move is a well organized chaos intertwined with "normal" operations.

Before the actual move, organizations spend hours upon hours with their internal staff and engineering & material handling companies analyzing how best to layout the new facility for optimal efficiency. The level of minutiae brought to the analysis can be mind numbing, but highly necessary to meet the goals of improved operational efficiency for a quick return on investment.

Over the years I have seen and been a part of companies that get through the analysis required for the optimal building and layout, then quickly move to the project management phase and forget about the move itself. This is a tactical error that is an an opening for a career limiting move. For whatever reason, warehouse staffs relate a warehouse move to the shipping and receiving work they do everyday. I get it. I have been there, done it and have the t-shirts.

The point is a poor move plan and execution can be:

- A strong six figure cost budget overrun on the move itself.

- An inventory nightmare for months after the move.

- An extremely painful time in a company's history, as it has repeated customer failures.

- Additional labor costs to make things right for the customer.

- Many times loss of job because the issues can quickly escalate out of control, as other operational problems arise from the new layout and equipment that spiral out of control with with repeated customer failures.

InTek Freight and Logistics Project Management Freight Solutions group has taken what has been learned over the years with its material handling market of flatbed projects for new warehouse and plant equipment fixturing and expanded into inventory warehouse moves for shippers.

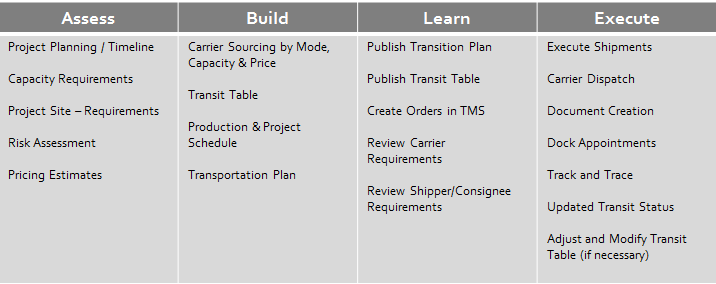

The below is the process flow chart InTek executes against, with its single point Move Manager. The key to success in any DC move is to have an inventory plan that drains the old facility, while loading up the new facility with inbound receipts to minimize duplicate handling and optimize outbound shipment performance of the "normal" business.

To close, a warehouse move used to be a once in a career project, but that is no longer the case in today's fast moving business environment. By bringing in a professional team to help the move process, logistics professionals can keep their eye on the new building and operational improvements that will elevate the overall customer service of its company to drive a competitive advantage.

If you're ready to take the next step, at InTek Freight & Logistics, we can help. Just tell us what you need and we'll discuss how our expertise can help with the unique shipping challenges your business faces. Rather do a bit more research first? View our Freight Guides for comprehensive articles and eBooks on all things freight and logistics.