Comparing Truckload vs Intermodal: 11 Differences Shippers Should Know

December 6, 2018 •Rick LaGore

Considering converting some of your truckload volume to intermodal or just adding intermodal into your logistics strategy for additional capacity? If so, we’re here to help. Our group handles both truckload and intermodal shipping for our customers, with our specialty being intermodal.

Our end goal of this article is for you to have the details necessary to determine when it makes sense to utilize intermodal and when truckload is the better option. In the end, we want you to be able to choose the mode that best fits your supply chain requirements.

Keep in mind, as you read through the details below, that neither is perfect for every situation. The key to having a successful logistics strategy is to choose what will work best for the various situations that will allow for a well-tuned optimized supply chain.

Comparisons Between Truckload and Intermodal:

-

Cost

-

Transit

-

Length of Haul

-

Weight

-

Value of Freight

-

Origin and Destination Pair

-

Flexibility

-

Scalability

-

Sustainability

-

Complexity

-

Congestion

Comparison of Intermodal versus Truckload

1. Cost

Let’s face it, cost is a top issue for logistics managers. Even when we hear service is what drove the initial call, if the cost is not there, many times logistics managers will accept lower on-time percentages.

With that in mind, when intermodal is an option on your origin-destination pair (O-D pair) it’s typically better than 10% cost savings on truckload for the high volume corridors and 8% to 10% lower than truckload on the less traveled lanes.

2. Transit

Truckload is the clear winner in the transit category. Intermodal is typically truckload transit, plus a day on freight that stays on the same Class I railroad and truckload transit, plus 2 to 3 days when the freight needs to be interlined between two Class I railroads.

3. Length of Haul

We would call the length of haul comparison a draw. Truckload has the ability to be an option on any length of haul and to any O-D pairing. Intermodal’s strength kicks in when the length of haul is 700 miles or more, as this is where the true efficiency can be leveraged on the rail portion of the linehaul.

The other limitation intermodal has, which you’ll hear more about shortly, is the O-D pairing needs to be advantageous to the intermodal ramp locations.

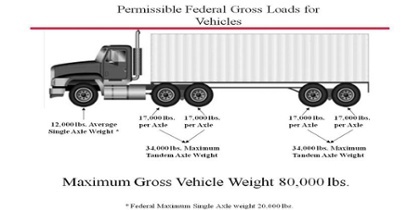

4. Weight

While the trailer and container dimensions of truckload and intermodal capacity is the same, the weight allowed to be loaded on truckload is a 2,500 pounds over intermodal. The reason for the difference is the combination of the more rigid intermodal container and chassis is heavier than a standard over-the-road (OTR) trailer.

While the trailer and container dimensions of truckload and intermodal capacity is the same, the weight allowed to be loaded on truckload is a 2,500 pounds over intermodal. The reason for the difference is the combination of the more rigid intermodal container and chassis is heavier than a standard over-the-road (OTR) trailer.

There are additional points intermodal shippers need to know about weight, as it is the #1 issue shippers have with their intermodal shippers and point to the following article to read more: Intermodal Weight - The Most Most Common Issue for Shippers New to Intermodal.

5. High Value of Freight

The value of freight has a couple schools of thought. Some prefer knowing that high value freight is handled by one driver only. They have the confidence that the driver will be under the load from origin to destination.

Our thought differs with this view, in that, we believe that having the freight on a train is far more difficult for thieves to access because the train is always in motion and when it is not it is behind secure areas.

Also, while the freight travels from origin to destination it is on a well car. The well car cannot be taken on the road and the bottom container on a well car cannot be opened, even for the craftiest thieves. Know there will be dray drivers on both ends of the linehaul, but the time on the road of a dary move is typically an hour or less, so unlike an OTR driver, there is a far less likely option of the driver leaving their cab to use the restroom or stop for food.

All said, we give intermodal the nod.

6. Origin and Destination Pair

Truckload is by far more flexible than intermodal when it comes to O-D pairings. As mentioned earlier, intermodal is locked to intermodal ramp locations; mileage of the rail portion; and to the distance from the origin or destination ramps. The best intermodal lane is 700 miles or more and no more than 100 miles from the ramp.

7. Flexibility

Intermodal is a more rigid method of shipping. There are cut times at the ramps to hold transits, and if issues happen on the rail, then the options are limited in that the container is on the rail until it isn’t, meaning that once the container is loaded on the well car it cannot be removed until it hits the destination ramp.

8. Scalability

Intermodal has the ability to scale far better than truckload. The reason being is when it comes to truckload shipments it is one truck and one driver that is fully responsible for the shipment from origin to destination. When it comes to intermodal it’s a many-to-many relationship.

Think of it this way: a dray driver can turn multiple times from an intermodal ramp to a warehouse and multiple drivers can be added to the dray segments of a shipment. Add to it, the class I railroads intermodal trains run an average of 280 trucks.

9. Sustainability

Intermodal is in a category by itself when it comes to this topic. Here are a few facts to back up the prior statement: one train moves an average of 280 trucks; intermodal is 4 times more efficient than trucking; rail can move one ton of freight 450 miles on a single gallon of fuel.

For those shippers looking for SmartWay certification through the EPA, intermodal will help to easily get them through the process as intermodal significantly helps the carbon footprint of a shipper’s supply chain.

10. Complexity

Intermodal does have some complexities that truckload does not. Some of these complexities are seen by a shipper and some are not. The one complexity that a shipper does not see is there are three segments of an intermodal shipment:

-

origin dray

-

linehaul on the rail

-

the destination dray.

The shipper never sees this complexity because they make the single phone call for their load just like they do for any truckload. The intermodal service provider (IMC) will handle and communicate and eventually invoice as a single shipment, like a truckload.

The complexity that a shipper will see is there is more diligence needed to load a 53’ intermodal container versus loading a 53’ dry van. The shipper will want to block and brace, as the freight moves within the rail segment much differently than on a truck because of harmonic vibration. For more on the topic of harmonic vibration read How to Ship Intermodal without Damage.

11. Congestion

Intermodal is a winner in the category of congestion, since it spends the majority of miles traveled between origin and destination on the rail lines, thereby by-passing miles of interstate travel.

Summary Comparison of Intermodal and Truckload

Intermodal Truckload Draw

Cost X

Transit X

Length of Haul X

Weight X

Value of Freight X

Origin and Destination Pair X

Flexibility X

Scalability X

Sustainability X

Complexity X

Congestion X

After reading the comparison, you can see why it was mentioned earlier that there is not a clear winner, as each has its strength.

The key to success is taking what you just learned above and applying it to the various freight loads your company moves. In some lanes, it will be an all or nothing mode choice, and in others it makes sense to augment both modes on a lane or choose certain days to run each mode.

If after reading through the comparison between intermodal and truckload and you are still interested, the next step is to consider your options of intermodal providers and let’s face it there are plenty of options. There are the top intermodal providers, with along with several other options like InTek Freight & Logistics that cover the intermodal service spectrum.

Comparing Intermodal Service Providers

Advantages to Working with One of the Top Intermodal Providers

There are many advantages to working with one of the top of mind intermodal providers - with stability and scale sitting in the number 1 and 2 position, but there are other considerations.

It’s (Typically) a Safe Bet

Hiring one of the top intermodal providers is typically a safe bet. As they say, “No one got fired for picking JB Hunt.” Most believe that since it’s a well know provider that it has to be a safe move.

The reality is every shipper’s supply chain is customized to meet their internal and external customers’ requirements, and while the “big” name has the brand recognition, there may be a more boutique provider that could be brought to the equation for a better fit of the shipper’s needs.

For that reason, ask the questions important to you versus reading off what is available on a sales brochure.

Strong Network of Assets

Volume, volume, and more volume is what the largest well know intermodal providers can bring to the table. If your business fits in with their volume needed to balance a lane, then you will have a real winner. These providers will bring the price and resources to knock your socks off.

Moving outside of their network or the largest providers already have a balance of freight in that lane, then makes sense to look to other intermodal providers. Also, not all providers have the same O-D pairing options, so here is another reason to look to other options.

Advantages with Intermodal Transportation Provider Not within the Top 10 Names

Ability to be Nimble

Executive leadership is there for its customers and has the ability to make decisions quickly. Essentially for the smaller intermodal providers every fish is large in their pond and will do all they can to keep the fish from jumping to an ocean.

Access to Top Talent

While the top intermodal brands differentiate themselves by having top talent in many areas, it is not always easy to access the talent so the shipper is pushed down lower into the organization on most matters.

This is not the case when working with a smaller intermodal provider because again the top talent is working in a smaller pool and often knows everything going on with most all of its business partners.

Also, it is a misnomer to think the smaller offices do not have access to market data, not engaged in the think groups moving the industry, etc.

InTek Freight & Logistics is probably one of the better examples of this one as our leadership sits on the boards of the Intermodal Association of North America (IANA) and the Transportation Intermediaries of North America (TIA). In addition to the leadership sitting on the boards, InTek also engages with several thought leadership groups with its Intermodal Index, such as The Journal of Commerce.

If intermodal still sounds like a good fit for your company, we recommend reading our in-depth article entitled The Completed Guide to Intermodal Transportation, which is comprissed of the following chapters:

- INTERMODAL VS. TRUCKLOAD SHIPPING: A SIDE-BY-SIDE COMPARISON

- IS INTERMODAL TRANSPORTATION THE RIGHT FIT FOR YOUR COMPANY?

- COMMON ISSUES AND MISCONCEPTIONS AROUND INTERMODAL TRANSPORTATION

- THE BENEFITS OF INTERMODAL TRANSPORTATION

- THE COST OF INTERMODAL TRANSPORTATION

- GETTING STARTED WITH INTERMODAL TRANSPORTATION

If you're ready to take the next step, at InTek Freight & Logistics, we can help. Just tell us what you need and we'll discuss how our expertise can help with the unique shipping challenges your business faces. Rather do a bit more research first? View our Freight Guides for comprehensive articles and eBooks on all things freight and logistics.

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (52)

- Freight Broker (58)

- Freight Forwarder (2)

- Intermodal Transportation (180)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (413)

- Logistics Service Provider (76)

- LTL (39)

- Managed TMS (49)

- News (38)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (120)

- Warehousing & Distribution (49)