We talk with shippers about truckload and truckload brokerage options every day throughout the year as they walk through their buying process and needs.

We talk with shippers about truckload and truckload brokerage options every day throughout the year as they walk through their buying process and needs.

Some of their most pressing questions include:

- Who are the largest truckload providers?

- Who are the largest truckload freight brokers?

- Why would a company use a freight broker?

- How much does truckload service cost?

- When does it make sense to use a freight broker versus when to use an asset motor carrier?

Typically, by the time the buyer gets to us, they have already decided that truckload is the freight mode they want to move their freight, which is understandable.

Truckload has long been the freight mode of choice when a shipper requires 53’ capacity for their vendors’ and customers’ freight.

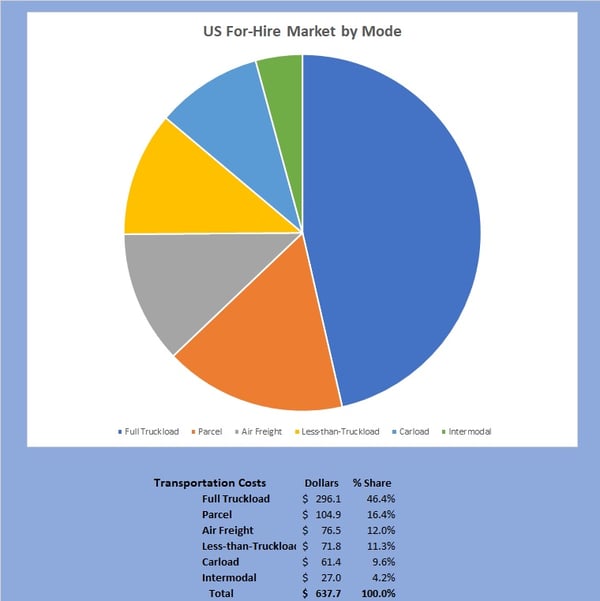

It is also the freight mode most people are familiar with and one that brings a tremendous number of positive attributes. This is illustrated by the fact that roughly 50% of all freight revenue moved through the freight market is truckload.

Our long-time readers know we cover the truckload topic in length, but we also have several engaging articles on intermodal. The reason we evaluate both truckload and intermodal options is because there is not a one size fits all solution, and diversification is the best method to protect a company’s supply chain on cost, service, and capacity.

With all the background behind us, let’s walk through the pros and cons of truckload to help 53’ capacity buyers know when it makes the most sense to use truckload in their logistics operations.

Pros & Cons of Shipping Via Truckload

As with any business or consumer purchase, there are always pros and cons to consider when determining the best buying decision. Purchasing truckload freight capacity is no different.

As with any business or consumer purchase, there are always pros and cons to consider when determining the best buying decision. Purchasing truckload freight capacity is no different.

Pros of Shipping via Truckload

Cost Effective

Truckload is undeniably the most cost-effective method to move freight from point A to B on short to medium distance lanes.

Flexible

The ability for a truck to pick-up and deliver to virtually any location that is land-based is by far its greatest attribute that is unmatched by any other freight mode. This claim may change in the future with the introduction of drones on a wide scale, but find it difficult to believe a drone will handle 53’ capacity and up to 45,000 pounds.

Visibility

The majority of trucks have GPS tracking devices on them, which gives shippers real-time visibility to their freight at all times.

Providers Are Plentiful

As the graphic illustrated at the start of this article, the truckload market is composed of 700,000 for-hire truckload providers accounting for 46.4% of the total for-hire freight spend in the US.

As the graphic illustrated at the start of this article, the truckload market is composed of 700,000 for-hire truckload providers accounting for 46.4% of the total for-hire freight spend in the US.

With that said, the truckload shippers have a tremendous number of service providers to move their freight locally, regionally, or across the country.

(As a side, we want to point out intermodal accounts for only 4.2% of the total freight market or 10% the size of truckload.)

Operation Teams Well Versed in the Mode

Trucks have been bumping loading docks for decades, making it the equipment shippers are most familiar with in the knowledge required to load to minimize shifting and damage.

Logistics teams also don’t need charts and graphics to figure a freight lane’s typical transit. They know transit can be found by taking the total miles and dividing by 50 miles to come up with the hours of transit. (50 MPH is the average speed a truck travels when considering traffic, city and highway miles.)

Multiple Service Options Available

Truckload has many different services offering to move freight:

- Dry Van

- Temp Controlled

- Flat Bed

- Tankers

- Expedited

- Single Driver

- Team Drivers

The number of options seem endless, which gives all shippers an opportunity to find a solution to meet their needs.

Cons of Shipping via Truckload

Limited Carrier Capacity on High Volume Lanes

Limited Carrier Capacity on High Volume Lanes

While there are 700,000 for-hire motor carriers in the market, there is limited capacity for an individual shipper needing to move a lot of freight traffic in a single lane over a short period because it takes a single driver, tractor, and trailer for each load.

What we are saying is there not an opportunity to turn these assets quickly to reposition for another load, particularly over long distances.

This is where intermodal has the advantage over truckload where a dray driver can turn several loads to an intermodal ramp in a day, bringing a great deal of capacity to cover promotions, peak, month end, quarter end, projects, etc.

This issue of capacity becomes a bigger issue for large distribution cities that have demand moving similar freight lanes. The FreightWaves Sonar reporting is a great tool logistics companies use to measure and forecast the coming challenges in markets they move freight.

Susceptible to Traffic, Road Construction and Weather

Truckload freight does have to meet the challenges of over-the-road infrastructure, traffic, construction, and weather. While other modes have similar issues, some are a little less susceptible than truckload.

Truckload freight does have to meet the challenges of over-the-road infrastructure, traffic, construction, and weather. While other modes have similar issues, some are a little less susceptible than truckload.

Extremely Diverse Supply Base

While 700,000 motor freight carriers is a blessing, it can also be troublesome in finding the capacity.

Many motor carriers don’t have a sales force, website, or other means of getting their message out to the shippers that need their service.

This is why many shippers utilize freight brokers in their logistics strategy.

Freight brokers and logistics service providers have a way to economically find freight capacity that shippers often do not. It is worth adding that many shippers are averse to utilizing a non-asset provider, so the diverse supply base is a big negative for them.

Not as Environmentally Friendly as Other Modes

There is no denying truckload is not the most environmentally friendly freight mode.

There is no denying truckload is not the most environmentally friendly freight mode.

Intermodal has truckload beat on this front with its characteristics to utilize trains to move freight over long-distance with little fuel and emissions.

The EPA’s SmartWay division measures a company’s environmentally friendly operation through a very complex reporting tool that evaluates a shipper, carrier, and logistics provider mode selection.

A sustainable supply chain does get a great deal of press, but it is not mandatory for a company to be within a certain specification on the level of its sustainability. This may change through regulations, but for now it’s not an issue that drives much change in how a shipper looks at its supply chain execution strategy today.

Can be limited on visibility

While we list visibility as a pro, there are limitations too.

Quite often, the GPS tracking is on the tractor, not the trailer, so the tractor could be moving, but not with the trailer one thinks it is. This can provide incorrect information.

Also, a great deal of truckload capacity is operated by motor carriers that do not have a website to provide tracking services off a GPS device, so the freight buyer still needs to call motor carrier to obtain the status of their load.

Wrapping up the Pros and Cons of Truckload

Shippers do have choices, but it is always a good practice to evaluate decisions to ensure that they are valid under a subjective prism that brings clarity to the situation.

We hope the breakdown of the pros and cons of truckload helps in your future 53’ buying decisions for finding the best fit freight mode for each of your shipping lanes.

If you're ready to take the next step, at InTek Freight & Logistics, we can help. Just tell us what you need and we'll discuss how our expertise can help with the unique shipping challenges your business faces. Rather do a bit more research first? View our Freight Guides for comprehensive articles and eBooks on all things freight and logistics.

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (54)

- Freight Broker (60)

- Freight Forwarder (2)

- Intermodal Transportation (184)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (420)

- Logistics Service Provider (77)

- LTL (39)

- Managed TMS (49)

- News (39)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (122)

- Warehousing & Distribution (50)