Temperature controlled freight is not just a need for the heat of summer months, but often is a year round requirement for some commodities.

Temperature controlled freight is not just a need for the heat of summer months, but often is a year round requirement for some commodities.

Temp-Controlled Commodities Include:

- Food (Fruit, Vegetables and Meat)

- Confectionary Products (Chocolate, Hard Candy, Gum & Gummies)

- Health & Beauty

- Nutritional Supplements

- Medical Supplies

- Pharmaceuticals

Now for those of you that blew by the list in skimming this article for nuggets of helpful information, let us draw your attention to pharmaceuticals as the once in a lifetime temperature controlled capacity constraining events is just about upon us with the distribution of the COVID19 vaccine.

While Pfizer and Moderna were the first to claim 90%+ success rates through their vaccine trials there are plenty more companies on the verge of stepping forward to indicate similar results, as the FDA COVID19 suggests.

The initial specifications around the COVID19 vaccines are required to be shipped and stored at below zero temperatures and with demand for the vaccine being driven with a US population of 330 million people and the worldwide population of 7.7 billion one can expect these shipments will take top dollar and priority over any other temp controlled freight.

With that in mind, it makes sense for temp-controlled shippers to solidify their plans to side-step the coming freight capacity crunch about to hit the market over the first six months of 2021.

Temperature Controlled Freight Capacity in Detail

The go to play for temp-controlled freight capacity has long been temp-controlled truckload, which provides the following benefits for shippers:

- The most freight capacity options through numerous motor freight carriers and freight brokers.

- Provides the largest payload space.

- Can be loaded to the greatest weight versus other land freight options.

- Faster transits than other modes.

Offers the most flexibility in unlimited origin and destination pairings.

Pros & Cons of Temp Controlled Intermodal - Historical Perspective

Temp-controlled intermodal has been available to shippers, but on a limited basis and with some drawbacks.

Temp-controlled intermodal has been available to shippers, but on a limited basis and with some drawbacks.

The closest option to truckload temp-controlled freight capacity has been accomplished through TOFC, trailer-on-flatcar intermodal service, where the reefer (refrigerated) trailer is loaded onto an intermodal flatcar at the intermodal ramp.

Motor carriers have often opted to use TOFC for their long haul demand requirements in capacity constrained years.

The plus with TOFC intermodal service is it has most of the positives of truckload reefer capacity, with the drawback on transit being roughly a day slower and the flexibility in origin and destination pairings is limited to 150 miles of their respective intermodal ramps.

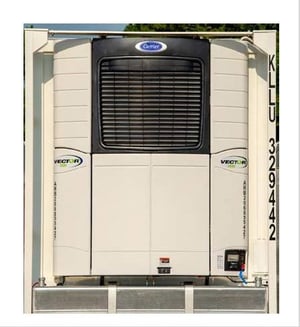

COFC intermodal, container-on-flatcar, has also been an option for temp-controlled shippers, but it came with the following negatives:

- COFC has historically had a lower weight capacity than truck or TOFC intermodal options.

- COFC could accommodate only 28 pallets versus 30 pallets on a truck or TOFC intermodal service.

The one positive COFC has over TOFC and truckload is on a good intermodal lane there will be a pricing advantage because four (4) 53’ COFC containers are loaded onto an intermodal well car where only two (2) 53’ trailers can be loaded on a rail flatcar, which increases efficiencies that translate into a lower price.

![]()

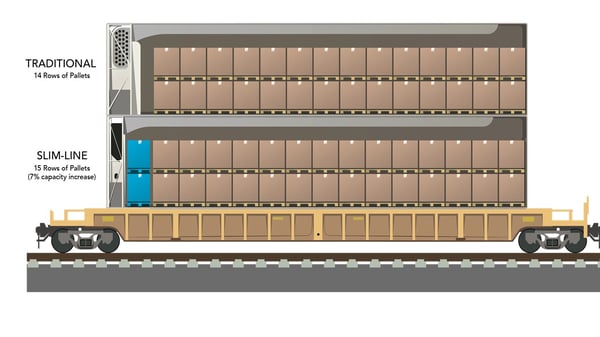

Temperature Controlled Intermodal COFC Container Advancements

Now for the great news. Technology and improved construction of COFC containers have evolved to the point where the shortcoming on pallets and weight has been eliminated, as the below COFC container specifications are outlined.

Temp-Controlled COFC Containers:

Loadable Interior Dimensions

Loadable Interior Dimensions

- Length: 605.00 inches

- Width: 97.25 inches

- Height: 97.50 inches (chute clearance height)

- Load Weight Limit

- 42,500 lbs

- Pallet Spaces (40”L X 48”W)

- 30 single-stacked or 60 double-stacked

- Pallet Spaces (48”L X 48”W)

- 24 single-stacked or 48 double-stacked

Since both the older COFC intermodal and the new SlimLine intermodal containers are in use, it is important to be very specific with the IMC providing the intermodal service on what is needed.

Best Commodities for Temp-Controlled Intermodal

Best Commodities for Temp-Controlled Intermodal

Produce

Produce

- Particularly hardy items, such as: Carrots, Citrus, Oranges, Onions, Celery, Broccoli, Potatoes, Apples, Pears, Melons

- Avoid any kind of berries or leafy greens.

- Be cautious of produce that has a relatively short shelf life, like bagged salad.

- Confectionary Products (Chocolate, Hard Candy, Gum & Gummies)

- Health & Beauty

- Nutritional Supplements

- Medical Supplies

- Pharmaceuticals

- Temp-Controlled Items that Require to be Temp Protected

- Wine

- Water

- Plastics

- Gummy Vitamins

- Some Food Items, Such As Protein Bars

- Commodities Sensitive to the Heat of Summer

- Commodities Sensitive to the Cold of Winter

Additional Technology Used for Temp-Controlled Commodities

Shippers requiring temp-controlled options for their product also have access to greater technology to better package and protect their freight, which for some is enough to maintain the required temperature in a standard 53’ dry van or intermodal container making for even more savings and improving capacity options.

Technology to Maintain Targeted Temperature in Dry Intermodal COFC:

- Blankets or Quilts

- Pallet covers to maintain target temperatures in a dry-van container.

Keep in mind blankets, quilts or other pallet covers do not bring temperatures down, but instead hold the temperatures within the pallets themselves.

It is also worth reviewing cost and service ROI that is associated with changing the packaging with the various pallet covers

Benefits to Reefer Intermodal vs. Reefer Truckload

For those new to intermodal, here is a quick list of its benefits:

For those new to intermodal, here is a quick list of its benefits:

- Lower Cost Alternative to Truckload

- Consistently, Reliable Service

- Helps Answer the Capacity Question

- Increased Level of Security

- Less Carbon Emissions as Compared to Truckload

- Drop Pools Available to Ease Operational Stress

Conclusion on Using COFC Intermodal for Temp-Controlled Freight

To conclude, shippers with temp-controlled shipping requirements have more options than ever before to protect their product while in transit to their customers.

There is not a one size fits all answer, so we recommend doing your homework and with the coming capacity demand coming as a result of the distribution of the COVID19 vaccine planning now will save hours and dollars later.

If intermodal is being considered, we’d love to be a part of the conversation. Roughly 90% of all the freight moved, outside of our freight management customers is 53’domestic intermodal with its direct relationships with all the class I railroads.

So, if you are still interested in learning more we recommend the following articles:

- The Complete Guide to Intermodal Transportation

- Cost of Intermodal Transportation Services (Rates, Fees & Variables)

- Freight Costs: An Insider’s Look on Freight Pricing Buyers Should Know

- Pros & Cons of Using Intermodal for Your Company's Shipments

- Asset vs Non-Asset Intermodal Freight Providers: A Detailed Comparison

Join the 20,000+ new visitors that look to the InTek Freight & Logistics Learning Center to help with freight and logistics problems that face their company.

For more on InTek Freight and Logistics, please visit our website and blog.

And if you find yourself looking for another way to beat the capacity challenges, please do not hesitate to reach out and contact us to discuss freight management services.

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (54)

- Freight Broker (60)

- Freight Forwarder (2)

- Intermodal Transportation (184)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (420)

- Logistics Service Provider (77)

- LTL (39)

- Managed TMS (49)

- News (39)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (122)

- Warehousing & Distribution (50)