Intermodal transportation continues to be a somewhat misunderstood freight mode. Unfortunately, this causes some shippers to not incorporate intermodal into their freight and logistics strategy.

Intermodal transportation continues to be a somewhat misunderstood freight mode. Unfortunately, this causes some shippers to not incorporate intermodal into their freight and logistics strategy.

A few years back we published an article on the misconceptions of intermodal that we thought would help bring more shippers into thinking about intermodal, but after speaking with so many shippers every year we found more was needed on the topic of intermodal.

The reason being is through our conversations we identified one of the main reasons for the apprehension of using intermodal still to this day is people question the legitimacy of all the intermodal benefits articles because they are not finding a balance of articles on potential negatives of incorporating an intermodal solution within their logistics strategy.

This is a fair objection because we all know there is not a one size fits all solution for any product or service, so to help balance all the benefits of intermodal we are writing this pros and cons article of shipping with intermodal.

So, with the basis of this article behind us, let’s start with discussion with the cons of intermodal before talking about the pros.

Cons of Using Intermodal Transportation Services

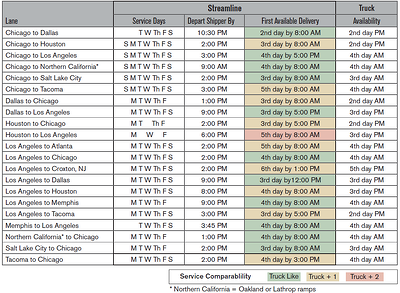

Transit

Intermodal transits do require more planning by shippers because the transit is slower than a typical truckload. The reason being is intermodal shipments are typically truck, plus a day. When an intermodal shipment requires two railroads to be utilized, a shipper can expect the shipment to be truck plus 2 to 3 days.

Intermodal transits do require more planning by shippers because the transit is slower than a typical truckload. The reason being is intermodal shipments are typically truck, plus a day. When an intermodal shipment requires two railroads to be utilized, a shipper can expect the shipment to be truck plus 2 to 3 days.

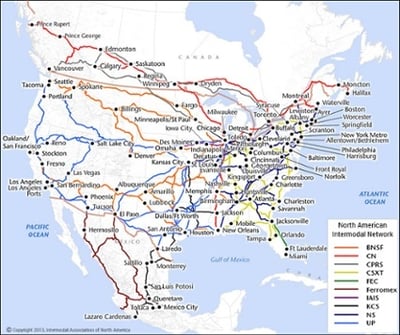

The reason why two railroads would be required is because the United States does not have one intermodal railroad that has tracking that spans the entire continent.

Also, there is not a single railroad that has tracking that spans the US, Canada or Mexico, so shippers looking for cross border shipments will have their intermodal containers interlined via rubber tire or steel wheel exchange to connect with the other railroad.

Block & Brace

The topic of blocking and bracing requirements for intermodal shipments often puts shippers on the sidelines because of the belief that it is difficult, time consuming and the expense is more than the savings.

The topic of blocking and bracing requirements for intermodal shipments often puts shippers on the sidelines because of the belief that it is difficult, time consuming and the expense is more than the savings.

The reason blocking and bracing is so important is because intermodal containers experience what is harmonic vibration. The vibration has the ability to move the contents of a shipment both horizontally and vertically in the container. To learn more read How to Ship Intermodal without Damage.

Quite often blocking and bracing is nothing more than staggering the pallets, as one would do for a truckload, then nailing a 2 x 4 footer to the floor to hold the last two pallets in place, so do not jump to the above conclusion. So, work with a reputable intermodal provider to help you through the process.

Not Every Commodity Can be Loaded in an Intermodal Container

Not every commodity can be shipped via intermodal. There are products that can be either restricted or prohibited.

Prohibited products are items that, without exception, are not allowed to travel via the rail infrastructure.

Restricted products are products that have rules and regulations that a shipper needs to follow for the shipment to move legally via rail. The shipper will be required to sign an agreement with the railroad that outlines the requirements, along with the cargo liability coverage. More often than not, a restricted commodity will have a cargo liability coverage less than the standard $250,000.

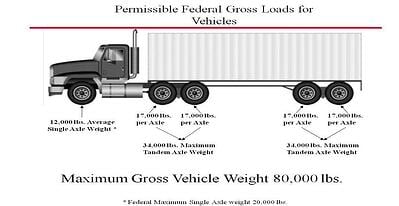

Weight

Weight is the number one issue for intermodal shippers.

Weight is the number one issue for intermodal shippers.

Unlike truckload’s ability to ship 45,000 pounds, an intermodal shipment can be loaded to 42,500 max.

This limit is driven by the combination of an intermodal container and its chassis is heavier than an over-the-road trailer.

Some bi-modal intermodal IMC’s can push the limit because their container / chassis is lighter, but will still not allow a shipper to load to the same weight as a truckload shipment.

We recommend shippers read Intermodal Weight - The Most Common Issue for Shippers to learn all there is about the topic to help get beyond this potential negative.

Limited O/D Pairings

Unlike truckload, intermodal cannot be a solution for every possible origin and destination zip code pairing.

Unlike truckload, intermodal cannot be a solution for every possible origin and destination zip code pairing.

The reason is there is a finite number of intermodal railroad ramps and dray typically needs to be within 100 miles of their respective ramp.

Map provided by IANA (Intermodal Association of North America.

Not an Option for Smaller Shipments

Intermodal may not always be an option because of the volume requirement to obtain contractual pricing. Contractual pricing that guarantees pricing and capacity for a year requires at least 3 shipments a week on the freight lane.

The volume requirement typically hits small shippers, but there are options.

A company can obtain intermodal capacity through the intermodal spot market.

Also, special project pricing for short term needs can also be an option for surge volume requirements over a short period of time.

Limited Market Providers

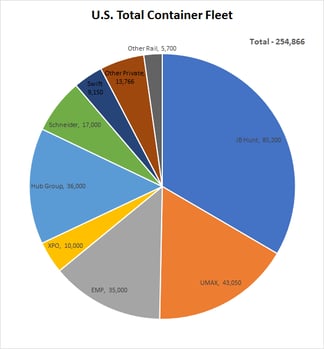

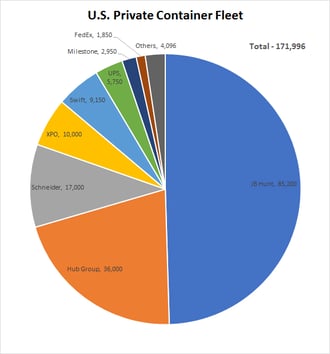

Another con for intermodal is the provider options are limited, as compared to truckload. Where there are 700,000 for-hire carriers the reality for intermodal IMC’s is less than 1,000 and the providers with actual intermodal container assets is 20, as seen in the graphic below.

Another issue to understand with intermodal, as it relates to providers, is the concept of beneficial cargo owner, also known as BCO.

When a shipper is requesting rates, the IMC needs to call out the BCO to the railroads its quoting the business. The reason for this is a railroad does not want to compete against itself on pricing, so when a quote is requested with the BCO named the railroad will check to ensure it is not doing the business through another IMC.

Cost

As trucks get more efficient, the cost competitiveness of intermodal has decreased on many lanes, so keep a close eye on market conditions to ensure intermodal continues to make sense for the business.

Pros of Using Intermodal Transportation

Cost

The key selling point with intermodal has been it holds a pricing advantage over truckload because of the efficiencies gained on combining the operational benefits of both rail and truckload, when a shipment is a good fit for intermodal service.

The key selling point with intermodal has been it holds a pricing advantage over truckload because of the efficiencies gained on combining the operational benefits of both rail and truckload, when a shipment is a good fit for intermodal service.

By using rail for the long haul segment and truck for the dray moves, a shipper wins with flexibility, service and cost. The win does come with some parameters on distance of origin and destination zip codes on the freight lane and the dray mileage distance on both the origin and destination of the shipment.

Here are some of the basic guidelines to consider when reviewing the cost benefit of intermodal:

- Less than 700 miles.

- Truck tends to be more competitive.

- 800 to 1,200 miles.

- Currently a coin flip, although becoming more favorable to intermodal.

- 1,200 to 2,000 miles.

- Clearly intermodal is more competitive.

The dray distance on an intermodal shipment does have an impact on the competitiveness of price. The rule of thumb for dray distances is it should be less than 100 miles from the intermodal ramps used to service the lane.

The less dray miles associated with a freight lane, the more competitive the intermodal rate will be against a truck rate. Along these lines, also keep in mind that as the total length of haul increases the lane does have the potential to take on longer dray miles and still be competitive against truckload.

When a freight lane is a good fit for intermodal, shippers can expect to save 5% to 10% against a truckload when using the spot freight market. On contractual lanes, there is roughly a 10% to 15% savings over contract truckload rates.

Large Amount of Capacity

Intermodal has the potential to throw a great deal of capacity to a shipper’s needs very rapidly.

Intermodal has the potential to throw a great deal of capacity to a shipper’s needs very rapidly.

The reason for this is because of the operational flow of intermodal, which is the dray at the origin and destination ramps are typically less than 100 miles allowing one dray driver to turn several times a day on multiple loads to the intermodal ramp to then move via a train of over 100 cars of double stacked intermodal containers. Compare that to truckload where a single driver under is under one truck for 2,000 to 3,000 miles before they can take another load.

This operational difference lets an IMC (intermodal marketing company), like a JB Hunt or an InTek Freight & Logistics, move 3 to 4 containers from a shipper’s dock to an intermodal ramp in a day providing a tremendous benefit in a time when driver shortages are frequently headline news.

Visibility

Intermodal provides a level of visibility that is often overlooked. Quite often shippers believe that once an intermodal container is loaded on a train they lose all visibility to the load.

Intermodal provides a level of visibility that is often overlooked. Quite often shippers believe that once an intermodal container is loaded on a train they lose all visibility to the load.

In reality, each container is scanned as it enters an intermodal ramp during the ingate process, then scanned when placed on the train’s wellcar. From there the train is tracked from the origin-to-destination intermodal ramps.

After the train arrives at its destination ramp the intermodal container is then scanned during the outgate process.

Reliable Transit

Truth be known, the intermodal railroading system is a finely tuned process where transit is both consistent and reliable.

If there is a transit issue, 9 out of 10 times it can be traced back to an issue with either of the dray segments of the shipment.

Environmentally Friendly

Intermodal is the most environmentally friendly option for moving freight over land, which is key as shippers build sustainable supply chains.

Intermodal is the most environmentally friendly option for moving freight over land, which is key as shippers build sustainable supply chains.

Intermodal is a key component for shippers, carriers and logistics service providers wanting to qualify their logistics and supply chains under the EPA SmartWay Program.

High Value

There are several reasons why intermodal is favorable for high value products.

- Base cargo insurance truckload carriers provide is $100k, with an option to purchase additional coverage. Contrast this with the standard cargo liability coverage offered by the majority of intermodal companies is $250,000.

- There are very few miles where a shipper’s freight is on the road and when it is, more often than not the dray carrier has no need to stop once they are under the load, since their dray miles average about 50 miles a load. This gives potential thieves less of an opportunity to intercept the load.

- Once the container is on the rail, it is virtually impossible to steal the contents. All intermodal ramps have a high level of security to enter, along with being barbed wire fenced.

Next Steps

If after reading this pros and cons of intermodal article has you interested in learning more about possibly utilizing intermodal for your business, we recommend the following articles to dig deeper into the topic.

The Complete Guide to Intermodal Transportation

The Complete Guide to Intermodal Transportation- Intermodal Weight - The Most Common Issue for Shippers

- Asset vs Non-Asset Intermodal Freight Providers: A Detailed Comparison

- Best Intermodal Companies (And How to Choose)

- Benefits of Intermodal. (Beyond the Typical List)

- Beneficial Cargo Owner (BCO): Definition & Importance

If you're ready to take the next step, at InTek Freight & Logistics, we can help. Just tell us what you need and we'll discuss how our expertise can help with the unique shipping challenges your business faces. Rather do a bit more research first? View our Freight Guides for comprehensive articles and eBooks on all things freight and logistics.

Get Updates

Featured Articles

Categories

- Freight & Shipping Costs (54)

- Freight Broker (60)

- Freight Forwarder (2)

- Intermodal Transportation (184)

- International & Cross Border Logistics (43)

- Logistics & Supply Chain (420)

- Logistics Service Provider (77)

- LTL (39)

- Managed TMS (49)

- News (39)

- Supply Chain Sustainability (12)

- Transportation Management System (37)

- Truckload (122)

- Warehousing & Distribution (50)